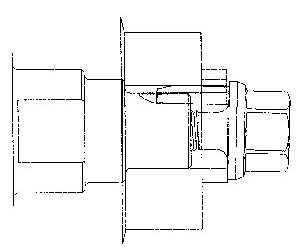

Crankshaft Slot

In this article we will discuss about:- 1. Meaning of Indexing 2. Methods of Indexing 3. Helical of Spiral Milling.

Meaning of Indexing:

Milling operations sometimes, require the rotation of job correct to fractions of minutes, for each groove, slot etc., to be cut evenly on the job surface. The accuracy of spacing of teeth is very important particularly when the work is of precision character e.g., gear teeth, shafts, cutter teeth etc.

The operation of rotating the job through a required angle between two successive cuts is termed as indexing. This is accomplished with the help of a milling attachment known as dividing head, which is an accessory to the milling machine. It helps to divide the job periphery into a number of equal divisions, i.e., square, hexagonal octagonal, etc.

ADVERTISEMENTS:

Dividing Head:

To rotate a job through required angle, one needs:

Crankshaft Slotted

(i) A device to rotate the job and

(ii) A source which can ensure that the job has been rotated through the desired angle.

In dividing head, the first requirement is met by an index-crank and the second by the index plate. The index-plate has a number of holes arranged concentrically, so that each circle has a number of holes equally spaced.

The crank has an arrangement in connection with the plunger-pin, which can slide through the slot and the crank is pivoted at the centre of a disc. This crank can be rotated about the axis and the plunger can be fixed at any desired hole.

These have a left crank arm with a compression slot that is secured by two pinch bolts and a right crank arm with an integrated spindle. These systems use external bearing cups and do not need a conventional crank puller. The left arms of these crank systems are used to adjust the bottom bracket bearings. I did my best to immobilize the crankshaft pulley/hb while tightening the crankshaft bolt. Well I didn't get near enough torque on it. Now after getting A REAL MECHANIC to get the hb off with a torch, I got problems. I need to replace the hb, gear and damaged belt. The keyway is not a slot anymore, but a valley.

The rotation of crank is transmitted through a gear to the job, so that the number of complete revolutions will result in certain revolutions of the job. The ratio of crank and the shaft on which job is mounted is 40 : 1, i.e., when the index plate makes 40 revolutions, the job makes one revolution.

For quick-placing of plunger and in order to avoid the counting of holes, fixed arms (sectors) are provided which can be set apart at any number of holes desired.

The following types of index-plates having the holes given against them are available.

Brown and Sharp:

Plate 1 : 15, 16, 17, 18, 19 and 20.

Plate 2 : 21, 23, 27, 29, 31 and 33.

ADVERTISEMENTS:

Plate 3 : 35, 37, 39, 41, 43, 47 and 49.

Parkinson:

Plate 1 : 24, 25, 28, 30, 34, 37, 38, 39, 41, 42 and 43.

Plate 2 : 46, 47, 49, 51, 53, 54, 57, 58, 59, 62 and 66.

Common Methods of Indexing:

There are five methods of indexing.

These are listed below:

(1) Direct indexing,

(2) Simple or plain indexing,

(3) Compound indexing,

(4) Differential indexing,

(5) Angular indexing.

1. Direct Indexing:

In this case, the dividing head has an index plate, fitted directly on the spindle. The intermediate use of worm and worm-wheel is avoided. The index plate has 24 holes and the periphery of job can be divided into 2, 3, 4, 6, 8 and 12 equal parts directly. This type indexing is most commonly used for indexing fixture.

2. Simple or Plain Indexing:

In this case, different index plates with varying number of holes are used to increase the range of indexing. The index is fixed in position by a pin called lockpin. The spindle is then rotated by rotating the handle which is keyed to the worm-shaft as shown in Fig. 16.61.

The following relation is used for simple indexing: T = 40/N, where T gives the number of turns or parts of a turn through which the index crank must be rotated to obtain the required number of divisions (N) on the job periphery.

Let us take an example of a gear blank on which 64 teeth are to be cut.

i.e., the worm is to be rotated by the handle through one complete rotation and two-third of the number of holes of any circle.

3. Compound Indexing:

The principle of operation of compound indexing is the same as that of simple indexing, but the only difference is that compound indexing uses two different circles of one plate and hence also sometimes referred to as hit and trial method.

The principle of compound indexing is to obtain the required division in two stages:

(i) By rotating the crank or handle in usual way keeping the index plate fixed.

(ii) By releasing the back pin and then rotating the index plate with the handle.

For example, if a 27 teeth gear is to be cut, then T = 40/27 i.e., the rotation required for one tooth spacing is 40/27 which may be written as 2/3 + 22/27 or 12/18 + 22/27.

So for each tooth, the worm will be rotated by 12 holes of 18 hole circle with the help of the crank and then the index plate is rotated by 22 holes of the 27 hole circle.

4. Differential Indexing:

Available number of index plates with different hole circles, sometimes confine the range of plain indexing. In such cases, differential indexing is found to be more suitable. Between the indexing plate and spindle of dividing head, a certain set of the gears is incorporated extra. Dividing heads are provided with such standard set of gears.

During the differential indexing, the index-plate is unlocked and connected to a train of gears which receive their motion from the worm gear spindle. As the handle is turned, the index plate also turns, but at a different rate and perhaps in the opposite direction. Differential indexing makes it possible to rotate the work by any fraction of revolution with the usual index plates furnished with the equipment.

For making the necessary calculations and to find the change of gears to be placed between the spindle and the worm shaft, use the following relation:

where N is the number of divisions to be indexed and n is a number slightly greater or less than N. The relation given by equation (1) will give a gear ratio to be placed on spindle (Driver) and the work shaft (Driven). The arrangement of gears can be in the form of simple wheel train or compound wheel train or compound wheel train depending upon the suitability and requirements.

The difference of N and n causes the index plate to rotate itself in a proper direction relative to crank. If (n — N) is positive, the index plate will rotate in the direction in which crank is rotated and if (n — N) is negative, it will rotate in opposite direction to that of crank.

5. Angular Indexing:

Instead of rotating the job through certain division on its periphery, sometimes it may be needed to rotate the job through certain angle. Angular indexing is used for this purpose. Since the crank and spindle ratio is 40 : 1 and hence when the crank moves through one revolution, the spindle or the job moves through 1/40 of revolution, i.e., the job will revolve through an angular movement of 9°.

If it is desired to index a job by 35 degree, then the index head movement required to perform the operation will be = (35/9) = 3(8/9) = 3 + ((8 X 3) / (9 X 3)) = 3 + (24/27), i.e., the crank must be turned three complete revolutions plus 24 holes in the 27-holes circle.

Helical of Spiral Milling in Indexing:

One of the important indexing operations to be performed on milling machine is the helical or spiral milling. Generation of flutes on twist drills, milling of helical and spiral gears, milling of worms and cutter, etc. are some of the examples of this class.

In the case of helical milling, the job is rotated and side by side it is moved linearly due to movement of table under the rotating cutter fixed in one position. This is done by connecting the worm shaft to the milling table feed screw with the help of a set of gears. Lead of the helix depends upon the rate at which the job is rotated with respect to table movement.

While performing helical milling, the following points must be taken into consideration:

a. The table of the milling machine must be set at an angle (equal to the helix angle) to the normal position of the table. This is done so that when the job advances and at the same time revolves also, the impression left by the cutter in the job will be identical to the contour of the cutter. The direction in which the table is swiveled determines the hand of spiral.

b. There must be a proper relation between the movement of job and table.

c. The job is to be fed to the cutter by the table movement.

Lead of helical milling machine is the distance through which the table moves when the spindle of dividing head moves through one revolution without any change in velocity ratio between the dividing head spindle and the table feed screw.

Sometimes it is necessary to introduce change gears between the worm shaft and the table feed screw, because when the table travels a distance equal to the lead of helix, the job must have completed one revolution. This can be achieved by introducing change gears. The formula given below holds good for the change gears.

The combustion of fuel shoots the piston straight down the cylinder, it’s the job of the crankshaft to convert this linear motion into rotation - basically by swinging around and pushing the piston back up the cylinder.

The terminology of a crankshaft is quite specialist, so we’ll start with naming a few parts. A journal is the part of a shaft that rotates inside a bearing. As can be seen above, there are two types of journal on a crankshaft - the main bearing journals form the axis of rotation for the crankshaft, and the connecting rod journals are secured to the ends of the connecting rods, which run up to the pistons.

For extra confusion, the connecting rod journals are abbreviated to rod journals and also commonly called crank pins, or big-end journals. The rod journals are connected to the main journals by webs.

The distance between the center of the main journal and the center of the crankshaft pin is called the crank radius, also called the crank throw. This measurement determines the range of piston travel as the crankshaft rotates - this distance from top to bottom is known as the stroke. The stroke of the piston will be twice the crank radius.

The rear end of the crankshaft extends outside the crankcase and ends with a flywheel flange. This precision machined flange is bolted to the flywheel, whose heavy mass helps smooth the pulsation of the pistons firing at different times. Through the flywheel, the rotation makes its way, through the transmission and final drive, to the wheels. In an automatic, the crankshaft is is bolted to the ring gear, that carries the torque converter, passing drive into the automatic transmission. This is basically the output of the engine - and power is taken to where it’s needed: propellers for boats and aircraft, induction coils for generators, and to the road wheels in a vehicle.

The front end of the crankshaft, sometimes called the nose, is a shaft which extends beyond the crankcase. This shaft will be locked to a toothed gear which drives the valve train through a timing belt or chain [or in highly technical applications, gear sets], and a pulley which provides power through a drive belt to accessories such as the alternator and water pump.

Main journals

Crankshaft Slot Machines

The main bearing journals, or just main journals, are clamped into the engine block and it is around these journals that the engine rotates. All crankshaft journals will be machined perfectly smooth and round, and often hardened The main journals are secured into saddles, in which a replaceable bearing insert will sit. The bearing is softer than the journal, and can be replaced as it wears and is designed to absorb small amounts of contaminants, if there are any, to save damaging the crankshaft. A main bearing cap is then bolted over the journal and tightened to an exact torque specification.

[Main journal diagram with bearings and holes]

The journals run on a film of oil which is forced into the space between the journal and the bearing through a hole in the crankshaft saddle and a corresponding hole in the bearing insert. With the correct oil pressure and supply of oil, the journal and the bearing should not make contact.

The connecting rod journals are offset from the axis of rotation, and are attached to the big ends of the pistons’ connecting rods. Confusingly, they are commonly also called crank pins or rod bearing journals. A feed of pressurised oil comes through an angled oil passage drilled from the main journal.

Some connecting rods have an oilway drilled through them to to allow oil to be sprayed onto the cylinder wall. When this is the case, the connecting rod journal bearings will have a groove to allow a feed of oil into the connecting rod.

Metal-to-metal contact is the enemy of an efficient engine, therefore the main journals and rod journals both ride on a film of oil that sits on the bearing surface.

Supplying oil to the main journal bearing is easy: Oil galleries from the engine block lead to each crankshaft saddle, and a matching hole in the bearing shell allows this oil to reach the journal.

The rod journal bearings require the same lubrication but they are rotating around the crankshaft at an offset. To get the oil to these bearings, oil passageways run inside the crankshaft - through the main journal, diagonally through the web, and out through holes in the rod journals. A groove in the main rod bearing allows oil to be continually forced down the passageway to the rod journals, assisted by being flung outwards by the centrifugal force of the rotating crankshaft.

The clearances between the journals and bearings are the main source of oil pressure in the engine. If the clearances are too high then oil flows out freely, and pressure is not maintained. Clearances that are too low will cause high oil pressure and risk metal-to-metal contact. It is therefore essential that the clearance between the bearings and journals are measured when an engine is rebuilt.

The crankshaft is subject to strong rotational forces, and the mass of the connecting rod and piston moving up and down exerts a significant force. Counterweights are cast as part of the crankshaft to balance out these forces. These counterweights allow for a smoother running engine and higher RPM.

A crankshaft will be balanced at the factory. In this process, the flywheel is attached and the entire assembly is spun on a machine which measures where it is out of balance. Balance holes are drilled in the counterweights to reduce weight. If weight needs to be added, a hole is drilled and then filled with heavy metal or mallory. This is repeated until the crankshaft is balanced.

Crankshaft Slot Machine

At some point along its length, two or more thrust washers will be installed to prevent the crankshaft moving lengthways. On the illustrated crankshaft, there are thrust washers on both sides of the central journal. These thrust washers sit between machined surfaces in the web and the crankshaft saddle - maintaining a specified small gap and minimizing the amount of lateral movement available to the crankshaft. The distance that the crankshaft can move from end-to-end is called its endplay and an acceptable range will be specified in the service manuals.

Some engines have these thrust washers formed as part of the main bearings, others, generally older types, use separate washers.

Both ends of the crankshaft extend beyond the crankcase, so some method of preventing oil escaping these openings must be provided. This is the job of the two main oil seals, one at the front and one at the rear.

The rear main seal is installed between the rear main journal and the flywheel. It is commonly a synthetic rubber lip-seal. The seal is pressed into a recess between the engine block and the oil pan. The seal has a shaped lip which is held tight against the crankshaft by a spring called a garter spring.

A failed oil seal is a major problem because they are adjacent to main journals which receive, and need, a good supply of pressurised oil. Combined with the spinning of the crankshaft, this leads to rapid loss of engine oil through any breach of an oil seal.

The front oil seal is similar to the rear, although its failure is less catastrophic and it is more easily accessed. The front oil seal will be behind the pulleys and timing gear.

An oil seal itself is a cheap part, but accessing it requires a lot of labour in removing the transmission, clutch, flywheel and possibly the crankshaft. It’s therefore recommended to replace the oil seals any time the engine is dismantled and the parts are accessible.

The basic crankshaft shown above is from an inline 4-cylinder engine. Other crankshaft designs will depend on the engine layout. This is a topic covered in more detail in the article about engine layout. But one point of note is that in V-shaped and W engines two connecting rods may share a single rod journal. Some typical crankshaft layouts are shown below.

A V6 crankshaft is somewhat specialist because it requires rod journals to be split to maintain an even firing interval. This necessitates the rod journals being split, or splayed, in what is known as a split-pin or split-journal design.

The crankshaft, being very sturdy, is a reliable component and crankshaft failures are rare unless an engine is subject to extreme conditions.

Without enough oil pressure, the crankshaft journals will make contact with the bearing surfaces gradually increasing the clearance and worsening the oil pressure. Taken to an extreme, this can lead to destroyed bearings and cause serious engine damage. Where journals are worn to below their service limits, or are no longer perfectly round, they will need to be ground as described below.

Constant forces on the crankshaft can lead to fatigue fractures, usually to be found on the fillet where the journals join to the web. A smooth radius of this fillet is critical to avoid weak spots leading to fatigue cracks. A crankshaft can be inspected for cracks using magnafluxing.

Crankshaft grinding

Journals wear over time. They may develop a rough surface, or become out-of-round or tapered. In these cases their surface can be restored in a process called crankshaft grinding. When a crankshaft is ground its journals will be reduced in diameter and so oversized, thicker bearings will need to be installed.

The cylinder capacity can be increased by moving the pistons over a longer stroke. The stroke of an engine is determined by the crank radius, being the distance of the rod journals from the main journals. A crankshaft with a larger crank radius will produce a longer stroke and a greater cylinder capacity - this is known as a stroker crankshaft. Shorter connecting rods will be required when a stroker crank is installed. Otherwise the pistons could travel too high in the cylinder - causing unacceptably higher compression or impacting on the cylinder roof.

Stroker crankshafts for frequently modified engines are sold in a kit with shorter connecting rods and pistons. A stroker kit for the Mazda MX5 Miata 1.8L engine can convert it to a 2L engine at a cost of around $5,500.

An alternative to installing a stroker crankshaft is to grind the rod journals to a smaller size, at an offset - thus moving the center of the journal away from the crankshaft centerline. This is illustrated above.

It can be seen that by moving the center of the rod journal, the crank radius has been increased leading to a longer stroke. This is specialist machining and the increase in stroke that can be achieved will depend on the thickness of the journals.

Most production engines use a cast iron crankshaft which is made by pouring molten iron into a mould. Forged crankshafts are used in some performance engines. A forged crankshaft is made by heating a block of steel until red hot, and then using extremely high pressure to form it into shape.

Once a crankshaft has been forged or cast, its journals and bearing surfaces are machined perfectly smooth. Oil passageways, or oilways, are drilled. Production engines will generally leave the webs with their original rough casting finish but performance engines will machine every part of the crankshaft to reduce oil drag.

The journals must be harder than their bearings to ensure that any wear occurs on the replaceable bearings and not the crankshaft, which should last for the lifetime of the engine. The manufacturing process will include hardening of these areas through nitriding or heat treatment.

Crankshaft Storage

Extremely high performance and custom crankshafts, are machined from a block of solid material, producing a billet crankshaft. Producing a one-off crankshaft by this process would cost a minimum of around $3,000 so it is reserved for competition racing and restoration situations.